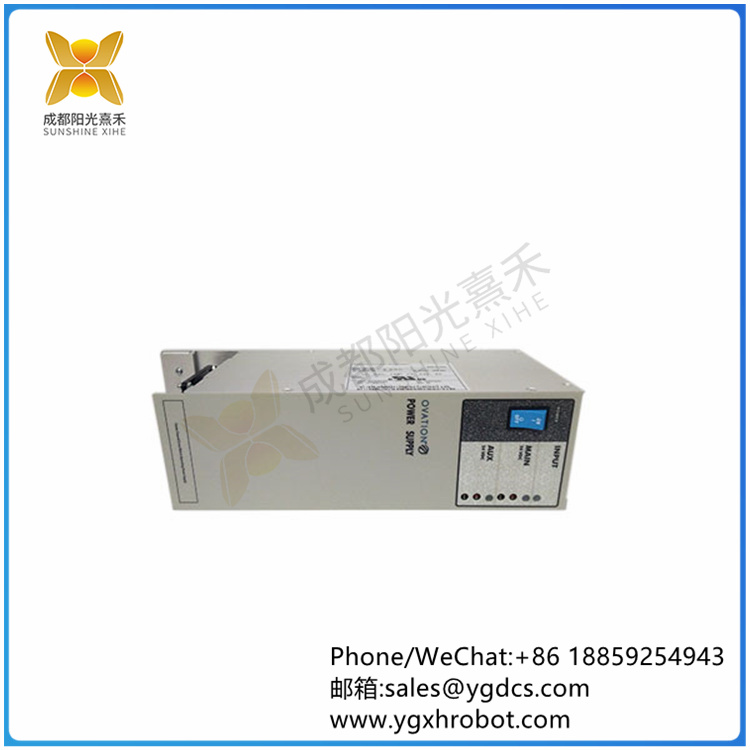

269PLUS-100N-120 With the in-depth advancement of global intelligent manufacturing, the demand for industrial robots and the robot reducer required by various industries is also increasing. Taking industrial robots as an example, the cost of precision reducer is about 30%, and as one of the core components of industrial robots, the cost ratio is high and the research and development is difficult. At the same time, China has broken through the key core technology of robots as an important strategy for scientific and technological development, and the development of domestic precision reducer technology is constantly accelerating.

Since 2019, Midea Industrial Technology has focused on the research and development and manufacturing of precision reducer, covering key areas such as gears, bearings, materials, simulation, friction and wear and lubrication, and is committed to providing precision reducer products with high reliability, strong consistency and short delivery time. Relying on 15000㎡ intelligent manufacturing plant, more than 50% of the core R & D team, industry-leading product process, and covering precision reducer performance testing, reliability testing IATF-16949 quality management system, Midea industrial technology SW-HG, SW-CG, SW-HD series harmonic reducer with more accurate, more durable, more reliable advantages to attract the audience stop.

In terms of product performance, Midea industrial technology high performance harmonic redu269PLUS-100N-120 cer using industry high standard materials, both high precision and high rigidity, through the industry high standard reliability laboratory certification, air travel, lag loss, transmission error, torsional rigidity indicators are comparable to industry benchmarks, such as product initial accuracy ≤1 Angle minute, 10000 hours after the precision degradation < 1 Angle minute, On par with the highest level in the industry.

In terms of product life, this series of products adopts high-precision simulation technology to optimize structural design, flexible wheel variable wall thickness design to adapt to large elastic deformation, and reduce the force of flexible bearing, greatly improve the life of the reducer, the test shows that the product life of more than 10,000 hours, in the industry leading level. And achieve continuous work without oil leakage, clean and efficient.

In terms of technological innovation, the original M tooth shape has a continuous multi-arc meshing surface, improving the simultaneous meshing rate of the tooth shape, greatly improving the bearing capacity and life, achieving a more durable application, more reliable, more stable and cleaner, and the overall performance has obtained CRRI certification and international leading identification

Not only that, the United States industrial technology high performance harmonic reducer has ac269PLUS-100N-120 hieved a positive design with independent intellectual property rights, and the layout of up to 100 patents, the overall performance has reached the international leading level, to achieve the United States precision transmission “from 0 to 1” breakthrough, for China’s industrial robot key parts import substitution, the rise of independent brands, industrial chain independent control to provide strong support. Adhering to the vision of “science and technology drive everything”, Midea Industrial technology will rely on multi-level, global R & D scale advantages, continue to increase reducer research and development and investment, with leading automation products and solutions to accelerate the automation of the global manufacturing industry, green transformation, create an efficient, green, intelligent industrial future.