330130-080-01-00 For the first time, Peel Magnetics offers a complete IO-Link Safety system for secure communication in the field: the system solution includes a master station, field equipment and compatible accessories. The first devices to be equipped with IO-Link Safety features in the Peel Magnetic portfolio include the safety light curtain PSENopt II advanced IOLS, the control unit PITgatebox IOLS and the IO-Link safety master station PDP67 IOLS. The full range of products offered by Piermagnetic makes it easier to integrate IO-Link Safety technology into equipment and machinery.

The non-proprietary standardized communication system IO-Link and all its benefits are now available for functional Safety: IO-Link Safety is now available for functional safety. Secure, standardized point-to-point communication integrates security sensors and actuators into any existing fieldbus system, independent of higher-level systems. The IO-Link Safety communication protocol has been globally standardized in IEC 61139-2, with maximum safety up to PLe of EN ISO 13849-1 (or SIL 3 of IEC 61508/62061). As a result, universal solutions offer greater flexibility, as users can meet a variety of security requirements using only one fieldbus.

Securely connect to the master station

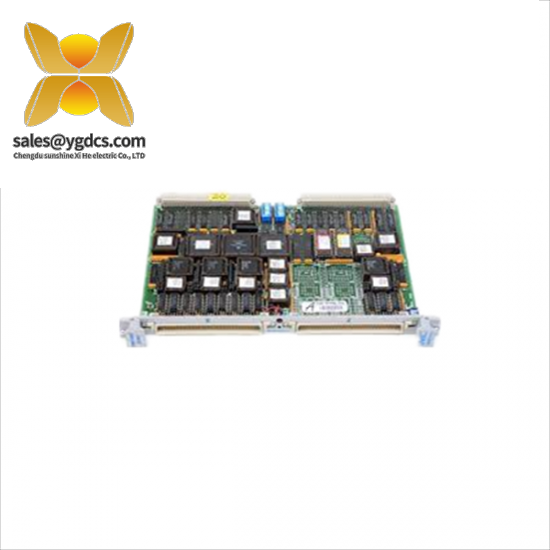

As an interface to the Safety controller, the IO-Link Safety master PDP67 IOLS enables bidirectional 330130-080-01-00 communication up to the field level. Safety sensors with IO-Link Safety can be connected to PDP IOL – in addition to IO-Link safety devices, standard IO-Link sensors and actuators can be connected, as well as classic safety sensors with OSSD outputs. Sensors such as the safety light curtain PSENopt advanced IOLS can be converted to OSSD technology.

Easily debug and replace equipment

IO-Link safety sensors from Pielmagneto provide important status information and more options in the field of intelligent diagnostics. Devices can be automatically identified and parameterized. This makes it easier to replace components and reduce equipment and machine downtime due to maintenance. In addition, fewer different equipment types are required, reducing the complexity of sourcing and creating warehouse space. As a result, costs can be reduced and productivity increased.

Manage data and diagnostics efficiently

Seamless communication with each sensor and actuator enables intelligent data evaluation: IO-Link Safety communication330130-080-01-00 takes place over unshielded cables and uses standard industry connectors. This can save time and cost when switching devices and improve availability.

Intelligent IO-Link safety devices also provide diagnostic functions such as self-diagnostic functions, enabling preventive repair and maintenance concepts. For preventive maintenance, for example, the single-beam assessment provides information on the signal strength of the safety light curtain PSENopt advanced IOLS. This can improve the productivity of the equipment or machine.

When it comes to IIOT, Pilz’s IO-Link Safety package supports the networking of plants and machinery to the sensor and field level through simple, non-proprietary solutions, thus opening up new possibilities for Industry 4.0.