Subtitle: The new 500CIM05 interface module brings higher data transfer rates and greater compatibility to industrial automation

Body text:

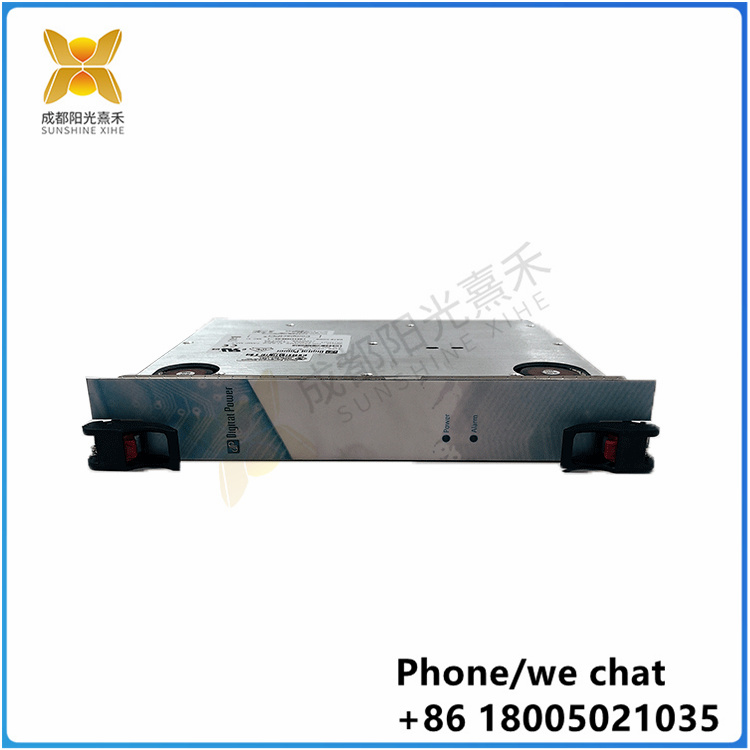

500CIM05 1MRB150077R1/B Interface module. With its excellent performance and innovative design, this new generation

of interface modules meets the needs of modern industrial automation for high-speed data transmission and seamless connectivity between devices.

High-speed data transfer: The 500CIM05 interface module supports the latest industrial Ethernet communication standards,

providing faster data transfer rates, ensuring real-time performance and efficiency, especially suitable for data-intensive industrial applications.

Enhanced compatibility: The module has been designed with compatibility in mind with a wide range of industrial equipment,

whether ABB’s own or third-party equipment, and the 500CIM05 provides a seamless integration experience.

Intelligent diagnostic function: The integrated intelligent diagnostic tool can monitor the communication status of the module in real time,

quickly identify and respond to abnormal situations in the network, reduce system downtime and improve production continuity.

Network Security Enhancement: Designed with the cybersecurity needs of industrial environments in mind, the 500CIM05 interface module

provides multiple layers of security to protect enterprises from the risks of cyber attacks and data breaches.

Easy integration and configuration: The interface design of the module is simple and clear, and it is easy to integrate with existing industrial

control systems or automation platforms, simplifying the complexity of engineering implementation.

Flexible application scenarios: The 500CIM05 module is suitable for a variety of industrial applications, including manufacturing, mining,

construction and food processing industries, especially for applications that require high communication speed and reliability.

The 500CIM05 1MRB150077R1/B interface module, as a key communication component provided by ABB, has the following advantages in practical applications:

Communication capabilities: The module supports a variety of communication protocols, allowing data exchange with different types of devices and systems, including fieldbus, Ethernet, etc., to provide efficient data transmission capabilities.

I/O connection: It can handle a variety of input and output types to meet the needs of different applications, such as digital volume, analog volume, pulse volume, etc., increasing its adaptability in automation systems.

Compatibility: Compatible with ABB’s AC500 series PLC control units, it can be used to build complex automated control systems.

Distributed control: As part of the ABB 800xA Distributed Control System (DCS), the 500CIM05 interface module can be integrated into a larger control system architecture, providing a modular design that allows interfaces to be added or removed as needed.

Flexibility and reliability: The modular design increases the flexibility of the system while being designed for use in industrial environments with high reliability and durability.

Environmental adaptability: The module can work stably in harsh industrial environments, and it is necessary to ensure that it is installed under appropriate environmental conditions to avoid damage caused by high temperature, high humidity and dust.

Power stability: Use a stable and reliable power supply to avoid voltage fluctuations affecting module performance and ensure the stability of data transmission.

Software configuration and technical support: During the system integration and debugging phase, you need to carefully configure the software to ensure that all communication Settings are correct. In case of technical problems, you can contact ABB’s official technical support for help.

Regular maintenance: Perform regular inspection and maintenance to replace aging or damaged parts in time to ensure continuous and reliable operation of the system