Body text:

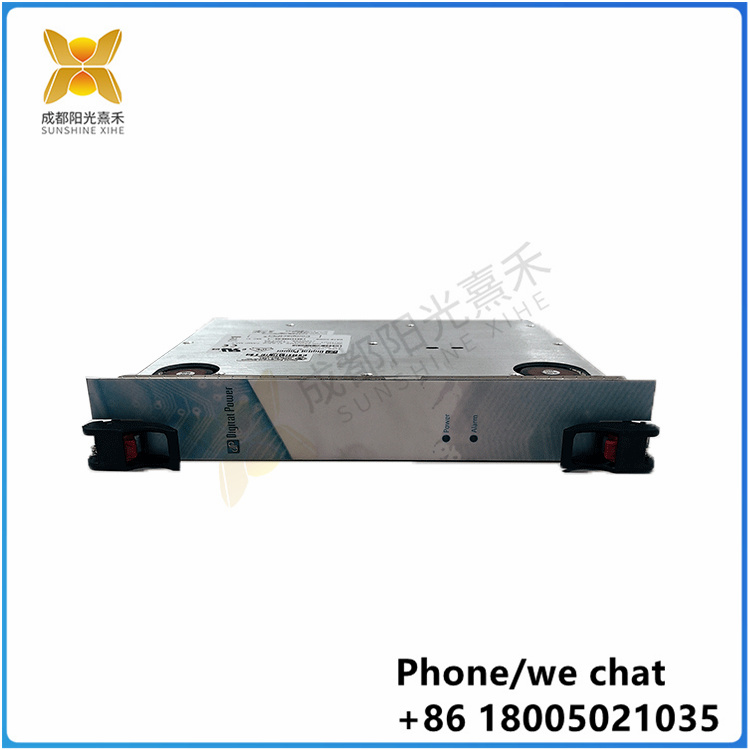

ABB, the global leader in industrial automation technology, today announced the launch of its newly developed 500CPU05 controller,

Model 1MRB150081R1/E. This new generation controller integrates ABB’s latest technology in the field of automation control,

and with its excellent performance and intelligent characteristics, meets the needs of modern industry for efficient, energy-saving and intelligent control.

Innovative performance: The 500CPU05 controller uses ABB’s latest control algorithms and semiconductor technology to

achieve faster processing speeds and increased system stability. Its multi-core processor and optimized programming environment provide users with powerful data processing capabilities.

Energy efficiency: Designed with a focus on energy efficiency, the 500CPU05 controller optimizes energy consumption while ensuring performance, helping companies achieve energy savings and emission reduction goals.

Intelligent Integration: The controller supports seamless integration with ABB’s other automation products and offers a wide range of interface options to simplify installation and configuration and improve system reliability.

Network security: In terms of network security, the 500CPU05 controller adopts advanced encryption technology and security protocols to ensure the security of data transmission and the protection capability of the system.

A wide range of applications: Whether in manufacturing, mining, construction or food processing, the 500CPU05 controller provides customized solutions to meet the specific needs of different industries.

Easy maintenance: The controller design takes into account the convenience of maintenance, simplifies the fault diagnosis and maintenance process, and reduces the operating costs of the enterprise

To ensure the security of ABB’s 500CPU05 controller in terms of network security, you can take the following steps:

Use the latest firmware and software versions: Make sure all software, firmware, libraries, and applications are up to date to keep your system and environment safe.

Compliance with international standards: The 500CPU05 controller follows generally accepted industry standards and practices, including the IEC 62443 standard, which covers the safe product development life cycle and the safety of industrial automation components.

Design security automation systems: Automation systems should be designed in accordance with IEC 62443-3-3, with risk and threat analysis as an entry point into the security planning process.

Data security protection: Regularly comb the data generated by the operation of the industrial control system, carry out data classification and classification, and use cryptography technology, access control, disaster recovery and backup technology to implement security protection of data.

Compliance with laws and administrative regulations: Important data and core data that are required for domestic storage by laws and administrative regulations should be stored in China, and data that really needs to be provided overseas should be evaluated for data exit security in accordance with laws and regulations.

Safety assessment pilot: Participate in the industrial control system network security protection capability evaluation pilot work, improve the evaluation mechanism, process and methods, and form replicable and scalable industrial control security solutions.

Identification of important systems: Explore the identification of important industrial control systems, research and formulate relevant documents to strengthen the protection of important systems.

Industrial ecological cultivation: Relying on pilot demonstrations, special projects, etc., to break through the key technologies of industrial control safety protection and improve the supply capacity of industrial control safety products.

Pay close attention to major industrial security vulnerabilities: Pay close attention to CNVD, CNNVD and other vulnerability libraries and patches issued by equipment manufacturers, and carry out strict security assessment and test verification before patch installation.

Boundary security protection: Separate the development, testing and production environment of industrial control systems, and use industrial control network boundary protection equipment for security protection